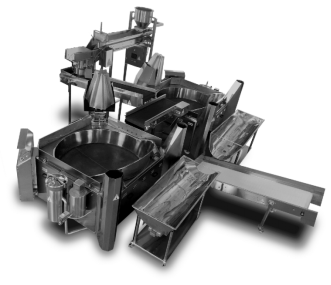

FRIED LINE

Designed and manufactured to weigh the product once it has been peeled.

Send it through conveyor belts to a cutter. Our cutter has various types of cutting, easy to use. Cut the potato according to the client's wishes, being able to choose up to three different cuts, chips, wavy and straw.

Once the potato is cut, it is sent by a high-speed conveyor that launches it into the fryer process, clean and very useful since these belts allow the water that the potato has and the peaks that the cutter may produce when cutting to be removed. In this way the oil is kept clean and long-lasting.

Our fryers are the ones with the highest performance, more production, less consumption. Various sizes and accessories, such as filters, levels, touch screen.

Afterwards, it is discharged to a vibrator or a sieve of your choice depending on the installation to cool and drain, finally the potato is sent through an exit belt where it is salted.

Video Fryer FT1870 100kg / h chips:

Video 2 Fryers FT2100 240kg/h chips:

Video Fryer FT1400 55kg/h chips: